Posted by ShopMoxa Expert on Jul 5th 2024

What Are the Different Types of Network Switches?

Network switches play a crucial role in modern networking, seamlessly connecting devices such as computers and servers across commercial and industrial landscapes. Network switches facilitate efficient data transfer, underpinning office operations and enabling real-time communication between industrial machinery and sensors.

As the cornerstone of digital infrastructure, these switches ensure uninterrupted connectivity in our interconnected world. This article delves into the various types of network switches, highlighting their significance and applications.

Content Outline

- What is a Network Switch?

- What are Industrial Network Switches?

- What is the Difference Between a Regular Switch and Industrial Switch?

- How to Select the Right Industrial Switch?

- Common FAQs

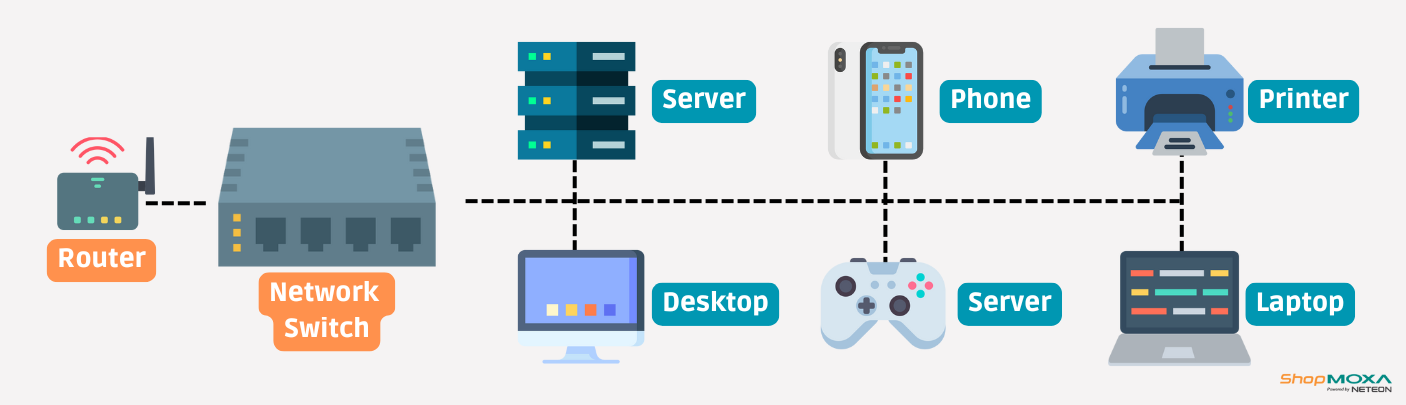

Three Types of Network Switches and Uses

A network switch is a device that connects and manages communications between multiple devices within a network, like computers and printers, directing data to its correct destination.

It's essential for efficient data flow in networks of all sizes, supporting seamless connectivity. Here are three common types of network switches:

1. Unmanaged Switches

These are simple, plug-and-play devices ideal for small networks, requiring no configuration and offering basic connectivity.

2. Managed Switches

Offering detailed control over network traffic, these switches allow for advanced configurations, security, and traffic management, suited for complex network environments.

3. Smart Switches (Semi-Managed)

Positioned between unmanaged and managed, smart switches provide some management features without the complexity, offering a balance of control and ease of use at a lower cost.

>> See More: Know More About PoE Swtich!

What are Industrial Network Switches?

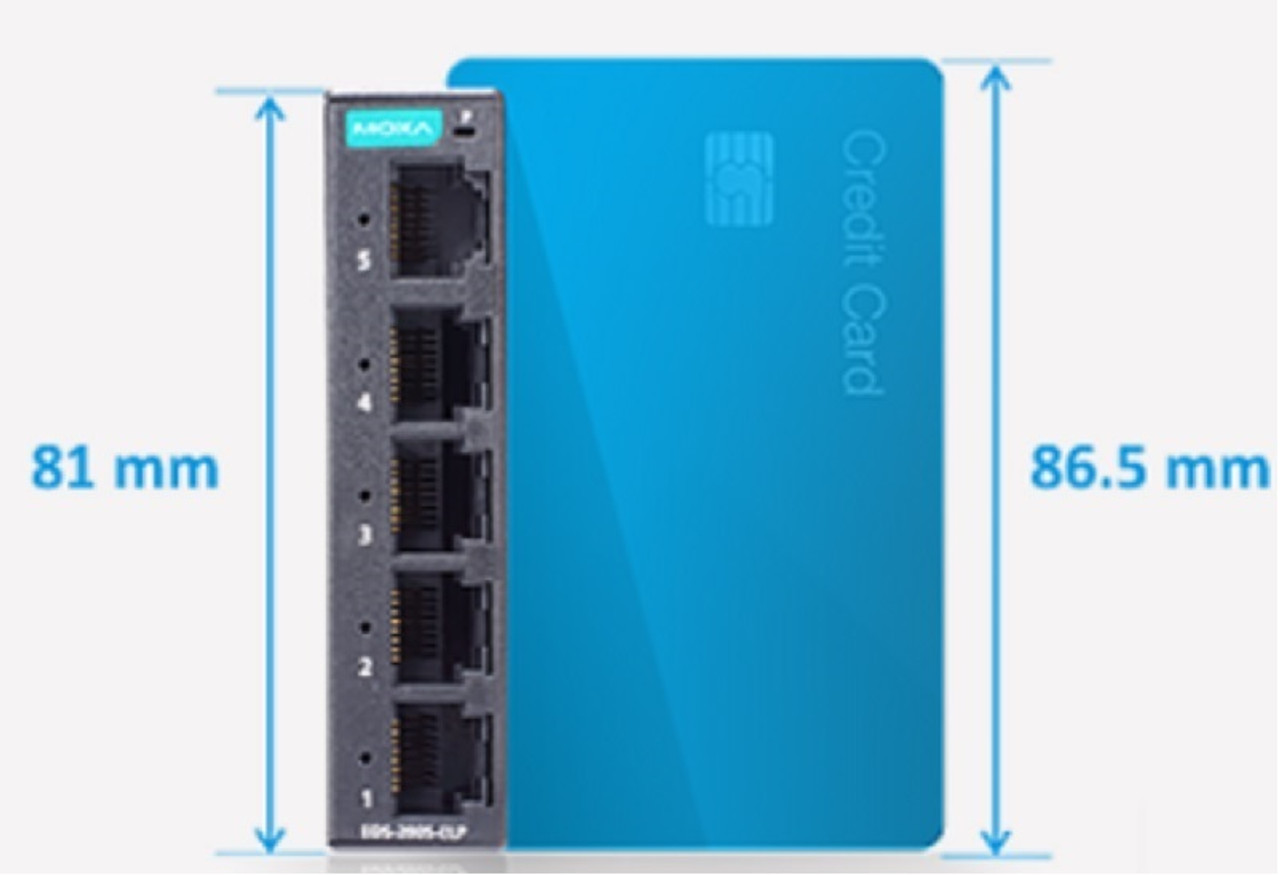

Industrial network switches are engineered for the extreme conditions of industrial settings, offering enhanced durability over commercial switches. They operate reliably under harsh conditions, including high temperatures, vibrations, and electromagnetic interference, ensuring uninterrupted industrial operations.

Industrial ethernet switches play a pivotal role by supporting high-speed data transfer and enabling real-time communication between devices.These switches are engineered to handle the large volumes of data typical in industrial processes, facilitating efficient and timely data exchange.

What is the Difference Between a Regular Switch and Industrial Switch?

The key difference between regular and industrial network switches lies in their design and performance capabilities, tailored to the environments they serve. Regular network switches are suited for controlled environments like offices and homes, where conditions are stable. Industrial switches, on the other hand, are built to withstand the harsh conditions of industrial environments.

- 1.Durability and Environmental Tolerance: Industrial switches are designed with rugged casings and components that resist extreme temperatures, vibrations, electromagnetic interference, and dust, ensuring reliable operation in challenging conditions where regular switches would fail.

- 2.Performance in Critical Operations: Industrial switches support high-speed data transfer and real-time communication essential for industrial processes, ensuring minimal downtime and maintaining continuous operation, a crucial factor where production lines and critical operations are concerned.

- 3.Enhanced Security and Reliability: Industrial switches often come with advanced security features to protect sensitive industrial data and support more reliable network connections, vital for maintaining the integrity of industrial operations.

How to Select the Right Industrial Switch?

Selecting the right industrial switch is crucial for ensuring the reliability and efficiency of your industrial network. Here are key factors to consider to match your specific environment and operational needs:

- 1.Operating Temperature Range: Industrial environments can vary widely in temperature. Ensure the switch you choose is rated for the specific temperature extremes of your environment, whether it's the heat of a steel mill or the cold of a refrigeration facility.

- 2.Network Speed Requirements: The speed at which your network operates is critical for timely data transfer and process control. Consider the data throughput and bandwidth capabilities of the switch, ensuring it meets the demands of your applications, whether for real-time automation control or high-volume data processing.

- 3.Reliability and Durability: Look for switches with a proven track record of reliability in industrial settings. Features like redundancy, failover capabilities, and robust physical construction can help ensure continuous operation and minimize downtime.

- 4.Environmental Resistance: Beyond temperature, industrial switches must resist various environmental factors such as dust, moisture, vibrations, and electromagnetic interference. Check for relevant certifications like IP (Ingress Protection) ratings that indicate the level of protection against these elements.

- 5.Security Features: Industrial networks often handle sensitive data that must be protected. Select a switch with strong security features, including port security, VLAN support, and firewall capabilities, to safeguard your network against unauthorized access and threats.

- 6.Scalability: Consider future growth and the potential need to expand your network. A switch that offers scalability in terms of port numbers and types, as well as software features, can adapt to growing or changing business needs.

Common FAQs

Where are industrial Ethernet switches used?

Industrial Ethernet switches are used in environments requiring robust network performance under harsh conditions, such as manufacturing plants, utility facilities, and transportation systems.

What is the difference between a network switch and an Ethernet switch?

A network switch is a broad term for devices that connect network segments, while an Ethernet switch specifically refers to switches that use Ethernet protocols for data transfer within LANs.

Which type of switches are the most commonly used industrial switches?

Managed industrial switches are most commonly used in industrial settings due to their ability to configure, manage, and monitor network traffic for optimal performance and security.

What is the most popular switch type?

In general networking, unmanaged switches are popular for their simplicity and ease of use in straightforward setups, while in industrial applications, managed switches are preferred for their advanced features and control.