Posted by ShopMoxa Expert on Jun 26th 2024

Benefits and Advantages of Fanless Industrial Computers

Protecting Your Operations: The Necessity of Rugged Fanless Industrial Compters

Industrial computers are the backbone of modern industrial operations, designed to endure the harsh conditions of industrial environments—where dust, moisture, extreme temperatures, and continuous operation are commonplace. Traditional industrial computers, however, face challenges that can hinder their performance.

To solve the problem, fanless industrial computers offer a robust solution to these challenges. By eliminating cooling fans, these systems adopt passive cooling methods, enhancing reliability, and durability. Read the article to know the benefits of fanless industrial computers.

Content Outline

- What are Fanless Industrial Computers?

- Why Should you Use Fanless industrial Computers?

- What are the Benefits of Fanless Computers?

- How to Select a Fanless Industrial Computer?

- Moxa Next Generation x86 Industrial Computers

- Common FAQs

What are Fanless Industrial Computers?

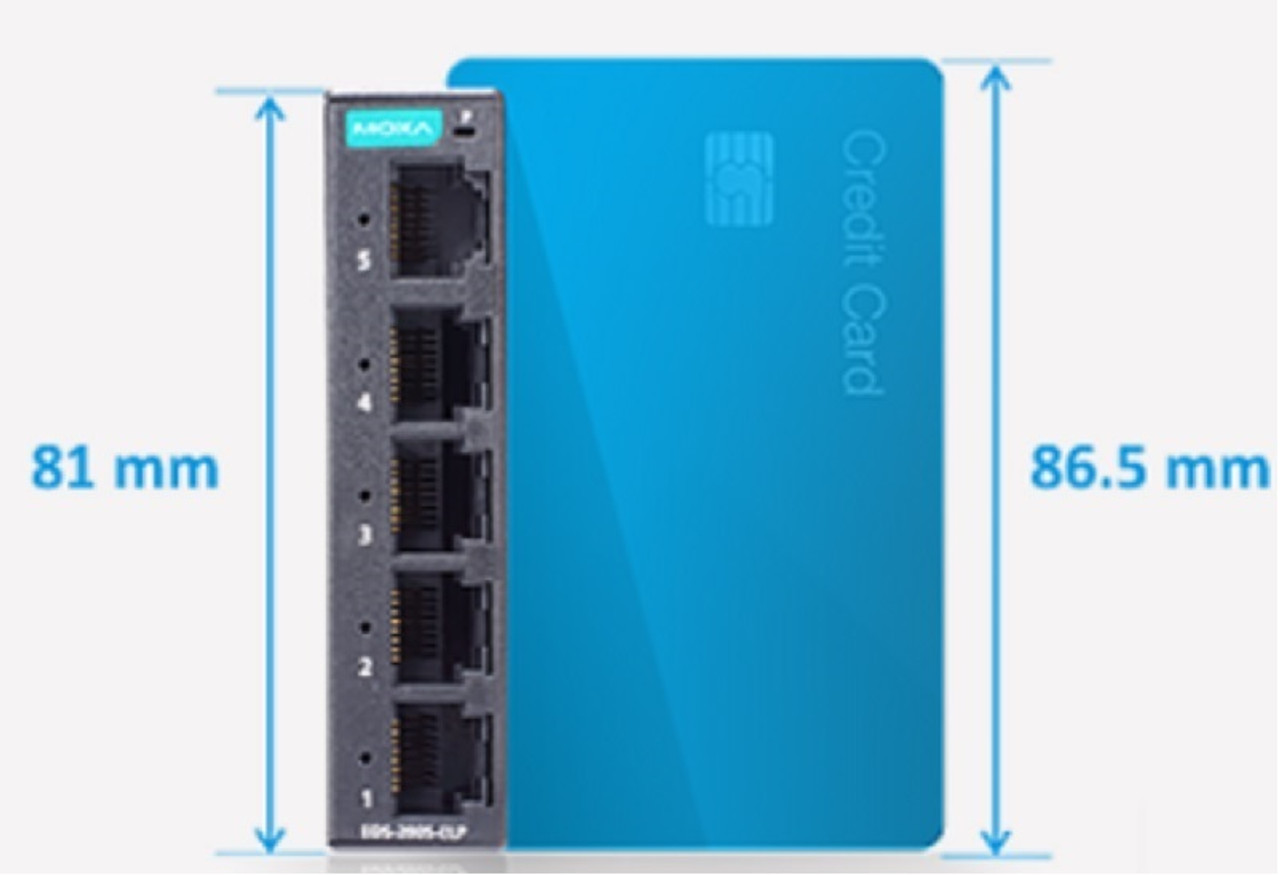

Fanless industrial computers are robust computing systems designed for industrial applications that operate without the use of traditional cooling fans. Unlike conventional fan-cooled systems, which rely on moving air to dissipate heat from critical components, fanless computers employ passive cooling techniques.

These techniques may include heat sinks, which are large metal components that absorb and disperse heat throughout their structure, and heat pipes, which efficiently transfer heat away from the processor to cooler parts of the device. By doing so, fanless industrial computers manage to maintain optimal operating temperatures, even in demanding industrial environments.

Why Should you Use Fanless industrial Computers?

The compelling reasons to use fanless industrial computers include the need for computing systems that can withstand the dust, debris, and potential moisture common in industrial settings without succumbing to heat-related failures or requiring frequent maintenance.

Additionally, the absence of moving parts significantly reduces noise, making fanless computers ideal for noise-sensitive environments. Moreover, their energy efficiency and long-term reliability make them a cost-effective solution for many industrial applications, ensuring consistent operation and reducing the total cost of ownership over time.

What are the Benefits of Fanless Computers?

Fanless industrial computers offer a multitude of advantages over their fan-cooled counterparts, making them a preferred choice for various applications. Here’s how they stand out:

Durability and Reliability

The absence of moving parts such as fans significantly reduces wear and tear, one of the primary causes of equipment failure. Without these vulnerable components, fanless computers boast a longer lifespan, providing a more dependable solution for critical industrial operations.

Improved Energy Efficiency

Fanless designs are inherently more energy-efficient. They consume less power as they do not need to operate fans for cooling purposes. This reduction in power consumption leads to lower energy costs, contributing to more sustainable and cost-effective operations.

Reduced Maintenance Needs

The elimination of fans means there’s no need for regular cleaning to remove dust and debris that can accumulate and clog traditional cooling systems. This not only reduces the maintenance effort and downtime but also extends the overall service life of the computer.

Enhanced Performance

Designed to withstand extreme conditions, fanless industrial computers excel in environments exposed to high temperatures, vibrations, and dusty or wet conditions. Their robust design ensures reliable operation even in the most challenging settings, where traditional computers might falter.

Quiet Operation

Without the constant hum of cooling fans, fanless computers operate silently, making them ideal for use in noise-sensitive environments such as hospitals, libraries, and research labs. This silent operation helps maintain a quieter, more focused work environment conducive to productivity and comfort.

How to Select a Fanless Industrial Computer?

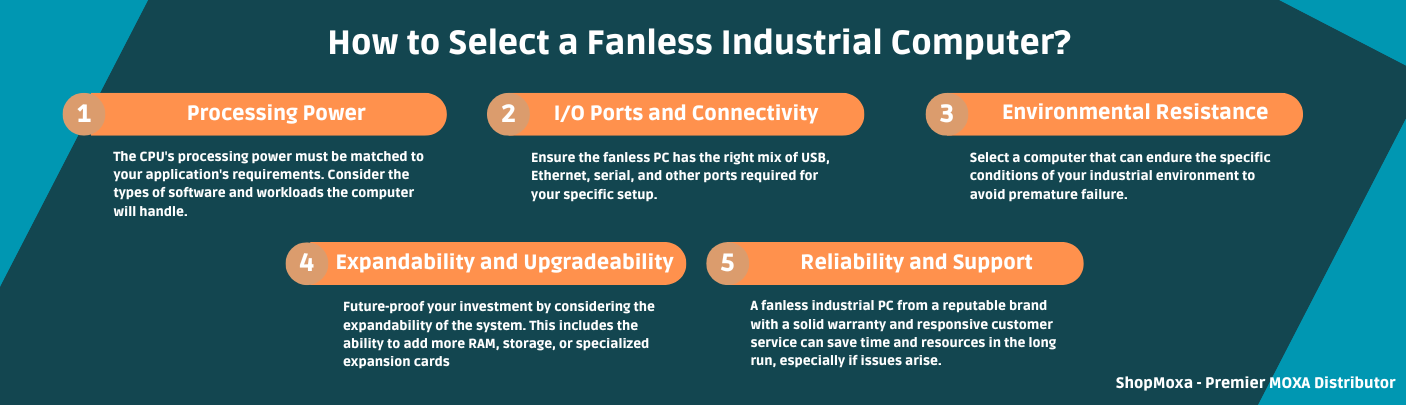

Choosing the right fanless industrial computer for your needs requires careful consideration of several key factors. These criteria ensure that the selected system will not only meet the current demands of your operations but also adapt to future requirements and challenges. Here's a brief guide to help you select:

1.Processing Power

The core of any computer, the CPU's processing power, must be matched to your application's requirements. Consider the types of software and workloads the computer will handle. For basic tasks, a less powerful processor may suffice, but for intensive applications, such as complex data analysis or real-time processing, a more robust CPU is necessary.

2.I/O Ports and Connectivity

The types and quantity of Input/Output (I/O) ports are crucial for connecting peripherals, sensors, and other equipment. Ensure the fanless PC has the right mix of USB, Ethernet, serial, and other ports required for your specific setup. Additionally, consider wireless connectivity options like Wi-Fi and Bluetooth if remote communication or network integration is needed.

3.Environmental Resistance

Given that fanless industrial computers are often deployed in challenging conditions, assess the environmental resistance of potential models. This includes temperature tolerance, dust and moisture resistance (often indicated by IP ratings), and the ability to withstand vibration and shock. Select a computer that can endure the specific conditions of your industrial environment to avoid premature failure.

4.Expandability and Upgradeability

Future-proof your investment by considering the expandability of the system. This includes the ability to add more RAM, storage, or specialized expansion cards. An easily upgradeable system ensures that your fanless industrial computer can evolve alongside your growing or changing needs without requiring a complete replacement.

5.Reliability and Support

Finally, factor in the manufacturer's reputation for reliability and the support options available. A fanless industrial PC from a reputable brand with a solid warranty and responsive customer service can save time and resources in the long run, especially if issues arise.

Moxa Next Generation x86 Industrial Computers

Empower Your Edge with Unmatched Reliability, Adaptability, and Longevity

Why Moxa's x86 Industrial Computers ?

Moxa's industrial computers are distinguished by their robust design, tailored to withstand the challenging conditions of industrial environments. With adaptable configurations and exceptional quality, they ensure reliability and scalability, meeting the dynamic needs of modern industrial applications.

Common FAQs

Where are industrial Ethernet switches used?

Industrial Ethernet switches are used in environments requiring robust network performance under harsh conditions, such as manufacturing plants, utility facilities, and transportation systems.

What is the difference between a network switch and an Ethernet switch?

A network switch is a broad term for devices that connect network segments, while an Ethernet switch specifically refers to switches that use Ethernet protocols for data transfer within LANs.

Which type of switches are the most commonly used industrial switches?

Managed industrial switches are most commonly used in industrial settings due to their ability to configure, manage, and monitor network traffic for optimal performance and security.

What is the most popular switch type?

In general networking, unmanaged switches are popular for their simplicity and ease of use in straightforward setups, while in industrial applications, managed switches are preferred for their advanced features and control.