MOXA MC-1220-KL1-T-S

MC-1200 Series- ON ORDER: 10 Units

- Can be backordered

- Contact Us for Availability or Possible Alternatives

| Exclusive Bulk Pricing on Select Products | ||

| Sign Up to Access. |

Features and Benefits

- 3 Mini-PCIe sockets for Wi-Fi, 3G, LTE, GPS, and mSATA expansion modules

- 7th Gen Intel® Core™ processor (Kaby Lake U)

- 2 built-in DDR4 memory slots; total capacity up to 32 GB

- Built-in TPM 2.0 module

- Variety of interfaces: 2 serial ports, 2 Giga LANs, 3 USB 3.0 (type A) ports

Introduction

The MC-1200Series computers are built around a 7th Gen Intel® Celeron® or Intel®Core™ i3, i5, or i7 processor and come with 1 HDMI display port, 3USB 3.0 ports, 2 gigabit LAN ports, and 2 3-in-1 RS-232/422/485 serialports. The MC-1200 is equipped with a 2.5” HDD/SSD slot and a built-inTPM 2.0 module.

Additional value and convenienceis provided through a modular design with three independent slotsfor flexible system integration and expansion. Users have the optionto add a variety of different communications modules, including Wi-Fi,3G, LTE, GPS, and mSATA expansion modules.

With UL Class 1 Division 2 compliance, the MC-1200 is sure to deliverstable and reliable system operation for oil and gas applications.Class 1 Division 2 (C1D2) is a certification issued to products thatallow them to be used in potentially hazardous environments. Examplesof hazardous work settings include locations where flammable or explosivegasses, certain chemicals, airborne fibers, or vapors could be excessiveunder abnormal circumstances.

The MC-1200is designed to operate reliably in extreme conditions, such as continuousexposure to low or high temperatures, humidity, high vibration, andpower surges, making them perfect for heavy industry, solar grid,water/wastewater, oil and gas, and transportation applications.

ProactiveMonitoring Function

Moxa Proactive Monitoring is a small-footprint, resource-friendly,easy-to-use utility available with some Moxa computers to track anumber of system parameters. You can view the current values for keyparts by simply clicking on the icons corresponding to the parametersin a Windows-based user interface. User-defined key part indicators(KPIs) are used to monitor the computer’s key parts. Visible and/oraudio alerts are triggered automatically via relays and SNMP trapswhen these KPIs exceed their preset threshold values, making it extremelyconvenient for operators to avoid system downtime by setting up predictivemaintenance tasks well in advance.

The Proactive Monitoring tool is currently availablewith the following:DA-820C SeriesDA-720 SeriesMC-1200 SeriesMC-7400 Series

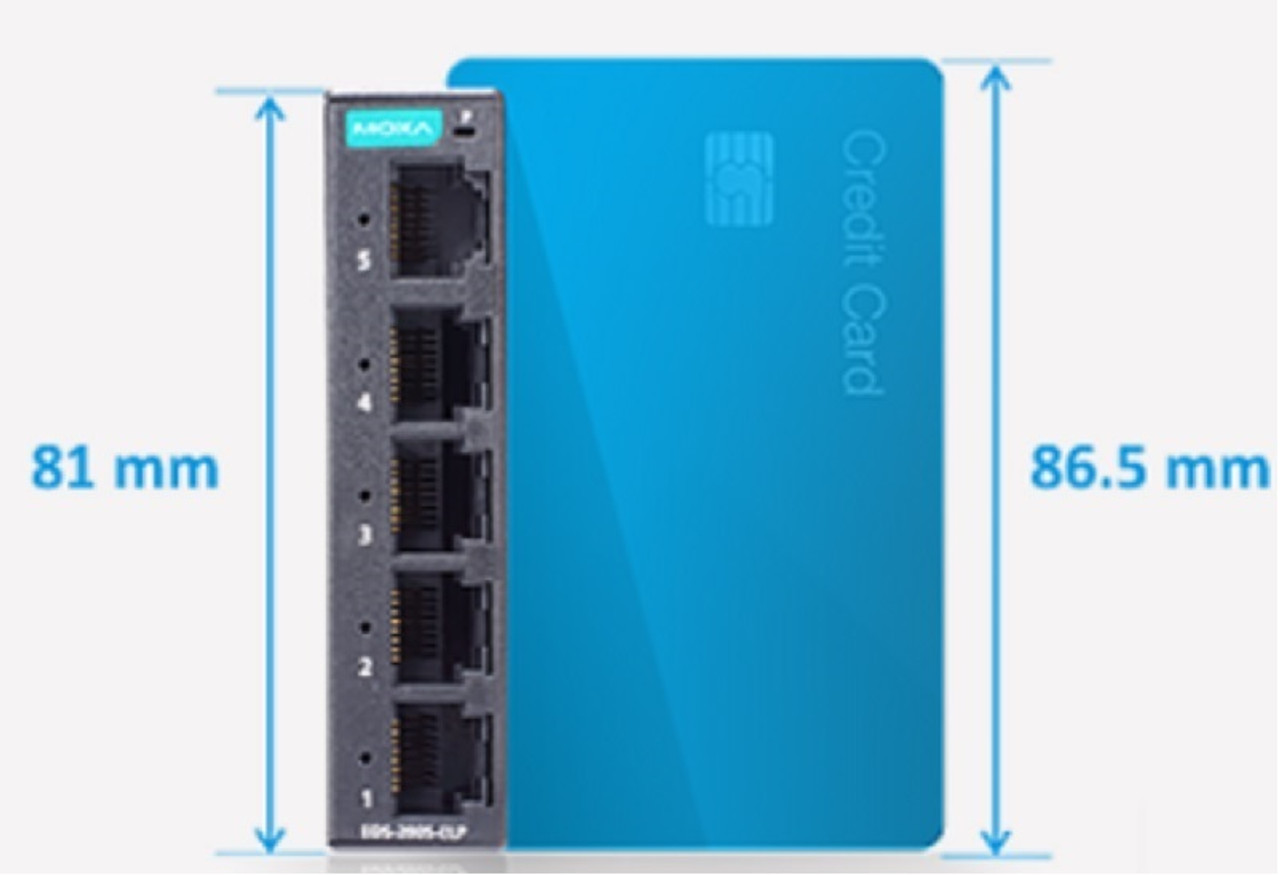

Appearance